- Contact Person : Mr. Chu Tony

- Company Name : Ningbo Zhuoli Moulds & Plastics Co., Ltd.

- Tel : 86-574-55110154

- Fax : 86-574-88200653

- Address : Zhejiang,Ningbo,ROOM502-503 No.C4 Ningbo Research&Development Park 299 guanghua Road, National Hi-Tech Zone, Ningbo, China

- Country/Region : China

- Zip : 315000

factory make plastic mould

Advantage(Why choose Zhuoli Mould?):

1. More than 20-years experience

2. ISO9001:2000 audited factory

3. Competitive price.

4. set of machines for mold making and injection molding

5. Custom R&D program coordination.

6. Application expertise.

7. Quality , reliability and long product life.

8. Mature, perfect and excellence but simple design

9. International standards, SAY, HASCO, DME, MISUMI, etc

10. Continuance service and support.

11. Diversified rich experienced skilled workers.Full

Important Note:

1. The injection mould is customized for our clients.

2. We do not sell ready-made injection mould, but custom injection mould. So, no price list available.

3. Quotation available after discussion on requirements and design.

Injection Mould experience:

1. Multiple cavities Injction Mould

2. Insert Injection Mould

3. Multiple slider action Injection Mould

4. Sandwich Injection Mould

5. Hot runner system

6. Injection Mould with international standard, like HASCO, etc.

7. Other custom Injection Mould

How To Custom My Own Injection Mould?

STEP | DETAIL |

1.Enquire /Quote | Quote competitive price according to customer's detail requirement. |

2.Negotiation | Quality,Technique requests,Mould material,Price,Delivery time,Payment,etc. |

3.Place order | According to customer's drawing or sample. |

4.prepaid | Customer T/T deposit to us to start to design mould. |

5.Mould design | We will communicate&exchange the opinion with customers during making drawing according to the sample. |

6.Design confirmation | Send mould drawing to customer for confirmation. |

7.Mould processing | Start to manufacture, we will sent photos to show tooling process. |

8.Sample confirm | Send the sample or as negotiation. |

9.Mass production | If customers need mass production plastic products, We can also offer. |

Description :

Mould Base | LKM,HASCO,DME |

Cavity/core material | 2738,2343,S130,2344,718,8407,S136,P20,KD-61,NAK80,H13 ect |

Cavity QTY | Single-cavity/Muti-cavity |

Runner | Yudo cold/hot runner |

Gate | Submarie gate,side/edge gate |

Mould lifetime | 500,000 shots |

Plastic part material | PC,PA,ABS,PVC,PA66,TPE,SAN,POM.etc |

Lead time | 20-40days based on different products |

Package | Wooden cases or cartons |

Port | Shanghai |

Design sofeware | UG/CAD/PROE |

How We Qualify Injection Mould:

After enquiry received, our engineers will analyze the drawing or samples and exchange the opinion about the potential difficulty or invisible problem. If needed, we will suggest right solution accordingly to make good plastic products while cutting cost.

Our quotation will be worked out after the initial mould design or products requirements are clear. In another words, both of two parties will understand whether the project is workable and what the right solution is before the price come out.

After order confirmed and the deposit received, our engineer will offer an analysis, in which customers will get the information including gate location, ejector pin location and other design details. For complex products, or large size products, especially those need hot runner, we will adopt mold flow analysis which can predict the potential defective or flaw, by simulating the injection molding processes, as shown in the picture below. In this way, customers will know the product condition before the mould making. Only after design approved, mould making can be started.

During the mould making process, we will apply the precision machines, for example, CNC machining, EDM, wire-cutting, especially, the 2.5 dimension measuring to check the electrode, parts, and products. In this way, we will find out the unexpected mistake in advance. In another words, it allows us to provide the good quality while saving the time and cost.

Our in-house injection department will test the mould by injecting the samples. The final qualified samples will be sent out to customers for approval

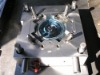

Factory image:

Equipment:

PRODUCT:

factory make plastic mould